Description

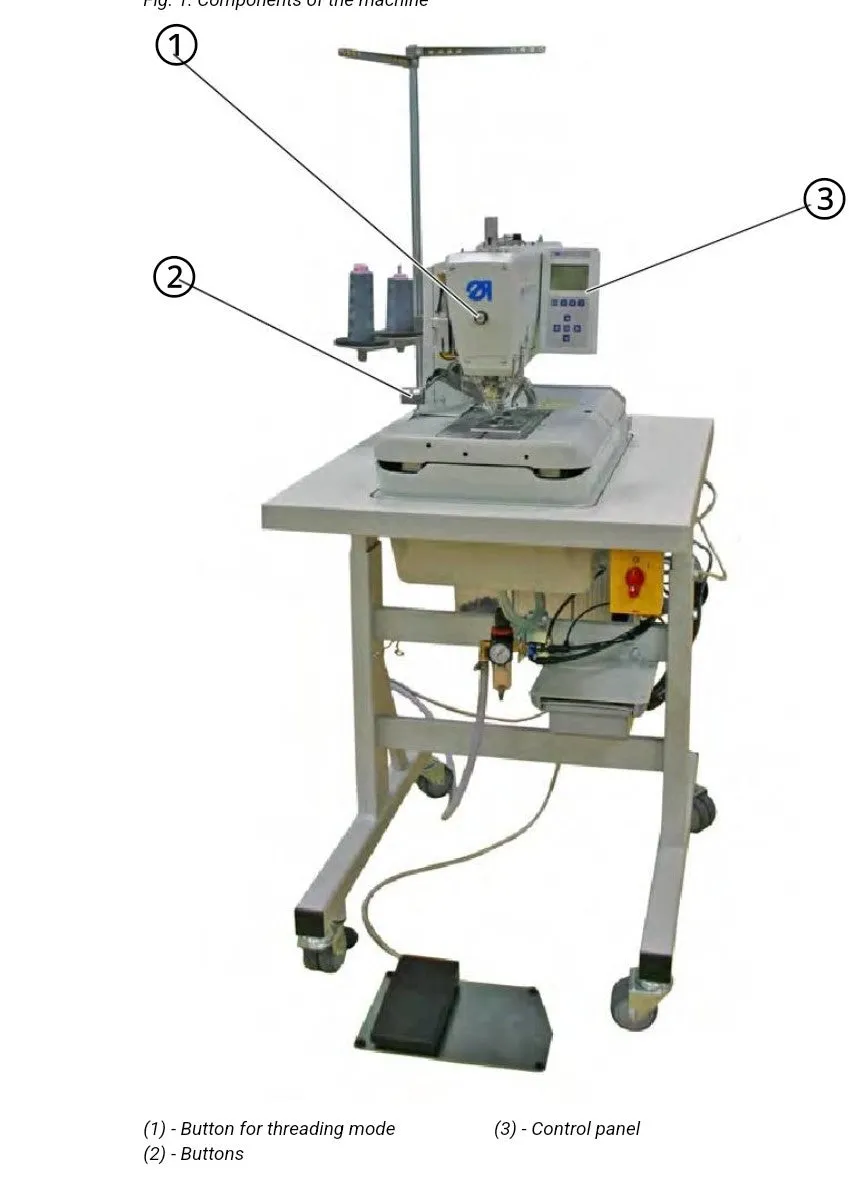

The Dürkopp Adler 580-341 MULTIFLEX is a state-of-the-art automatic buttonhole machine designed for producing high-quality buttonholes in jeans, sportswear, and workwear. With a legacy dating back to 1935, this machine is renowned for its flexibility and exceptional performance in buttonhole manufacturing.

Key Features:

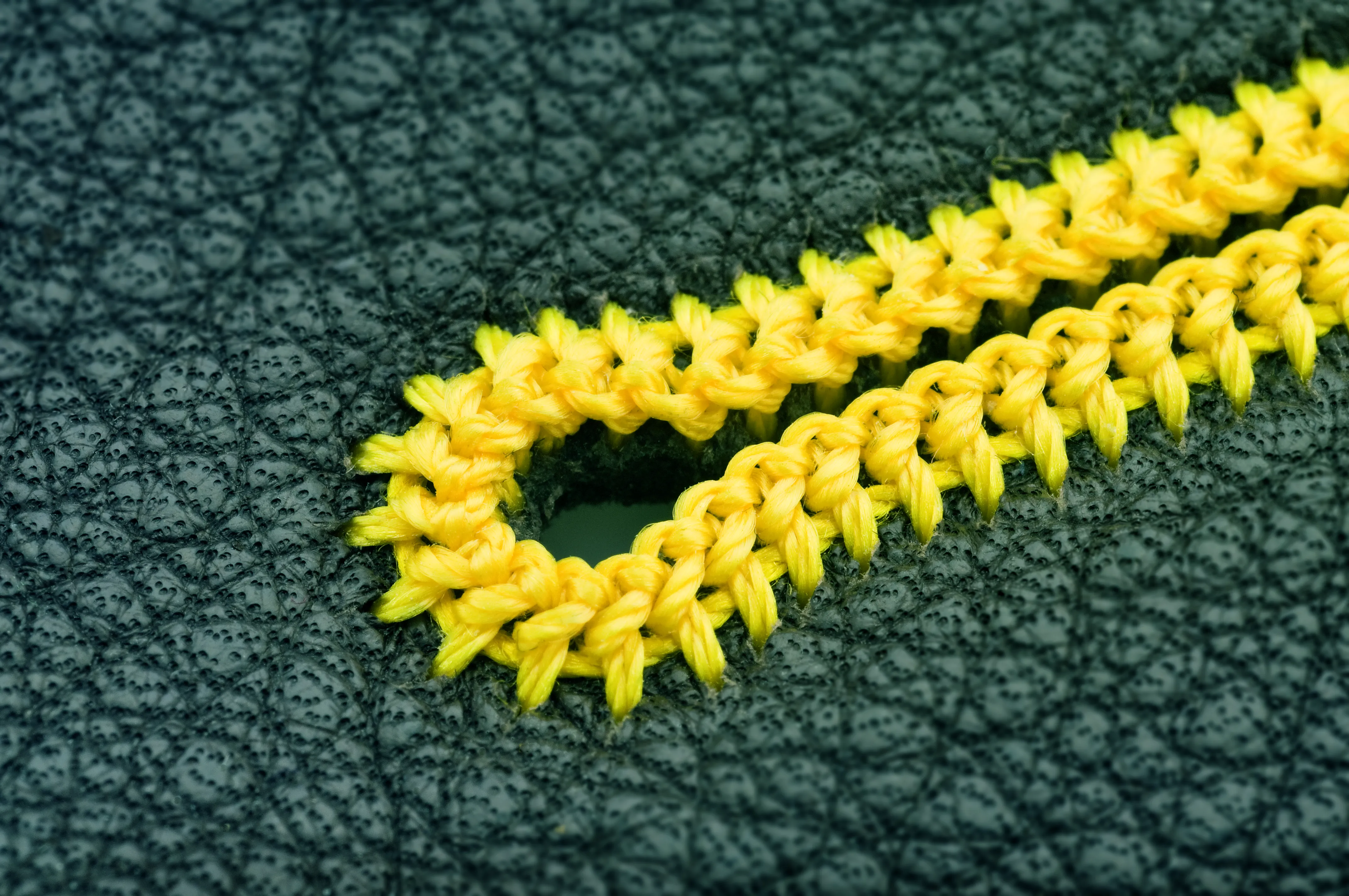

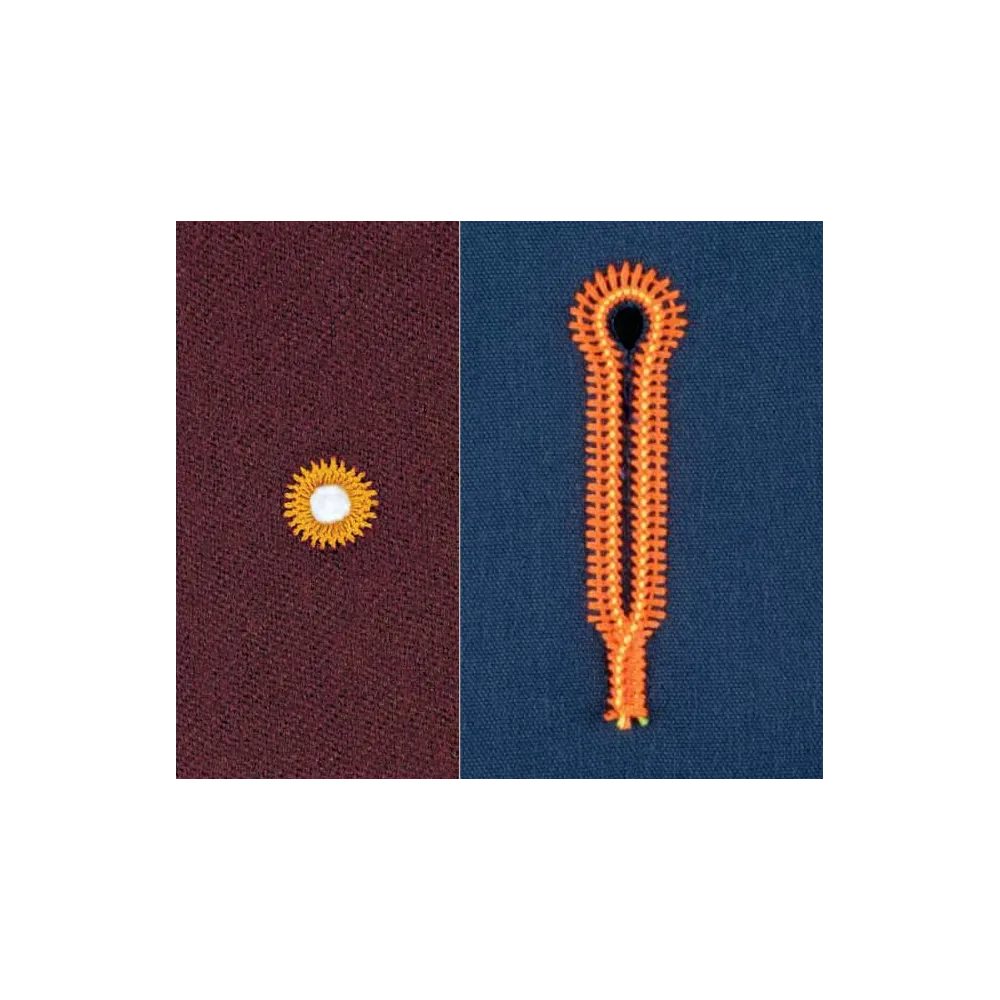

- Versatile Buttonhole Production: Capable of sewing buttonholes of various shapes and lengths, with or without gimp thread, as well as round eyelets, all without the need for time-consuming changes of cutting blocks or knives.

- Efficient Operation: Equipped with a trimmer for needle thread, looper thread, and gimp thread that eliminates the need for subsequent trimming, allowing different buttonholes to be produced seamlessly at a single workstation.

- Automatic Length Allocation: The machine automatically determines the required cut length, ensuring maximum efficiency even for small lot sizes, with a maximum sewing length of 36 mm.

- User-Friendly Programming: The Dürkopp Adler control system allows for easy programming of up to 50 buttonhole designs and the capability to sew 25 sequences of up to 9 different programs, either sequentially or individually.

- Optimized Threading and Cutting: Features rapid color change capabilities, optimized sewing kinematics, and a fast cutting system for minimal cycle times.

- Enhanced Visibility: The semi-submerged sewing head provides an unobstructed view of the work area, while the integrated LED sewing light improves visibility on low-contrast materials.

- Robust Performance: With automatic cutting force adjustment and no need for adaptation between different cutting blocks, this machine is built for durability and ease of use.

- Innovative Waste Management: Includes a suction device for cutting waste and an integrated test and monitoring system ("Multitest") for consistent quality control.

Technical Data:

- Maximum Sewing Length: 36 mm

- Buttonhole Width: Adjustable (up to 8 mm for taper bar; up to 32 mm for eyelet buttonholes)

- Cutting Block: Includes options for single cuts and round eyelets (3 mm and 4 mm diameter)

- Programmable Designs: Up to 50 buttonholes

- Sewing Sequence: 25 sequences with up to 9 different programs

- Thread Trimming: Automatic trimming of needle thread, looper thread, and gimp thread

- Suction Device: For cutting waste

- Control System: Dürkopp Adler's proven operating concept for easy parameter programming

- LED Sewing Light: Standard feature for enhanced visibility.

please refer to for more technical specifications.

Applications:

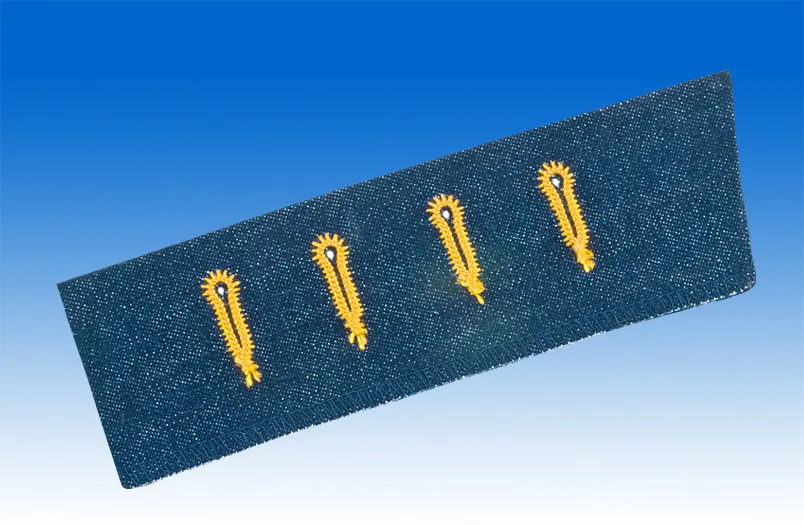

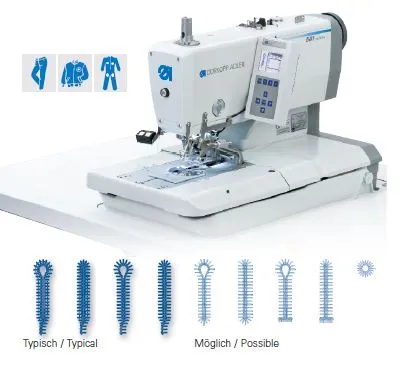

Typical Applications:

- With Gimp and Taper Bar: Ideal for creating durable and decorative buttonholes.

Possible Applications:

- Without Gimp: For a cleaner finish.

- With Taper Bar: Enhances the buttonhole's strength.

- Cross Bartack or Round Tack: Offers additional design options for buttonholes.

- With or Without Eye: Flexibility to produce various styles based on garment requirements.

The 580-341 MULTIFLEX is suitable for a wide range of applications, including buttonhole plackets, decorative buttonholes for sportswear and safety wear, and round eyelets for uniforms and other garments.

In summary, the Dürkopp Adler 580-341 MULTIFLEX offers unmatched flexibility and efficiency in buttonhole production, making it an ideal choice for modern garment manufacturing.

Note-The Dürkopp Adler 581-341 comes with a delivery timeframe of approximately 6-8 weeks from the date of order placement, plus shipping time. For those ordering two sets, the estimated sea freight cost to Singapore is about EUR 450(SGD 643). This makes it a convenient option for businesses looking to enhance their production capabilities with this advanced sewing and cutting machine.

Downloads

![Yonex 26088 Women's Skort [Black] Yonex 26088 Women's Skort [Black]](https://www.untopsed.shop/image/yonex-26088-womens-skort-black_zO8ATX_300x.webp)